Do you want to know how to scaling production processes with Dynamics 365 for Manufacturing. Here are some technical considerations and solutions.

Think of how a complete change in your production method can lead to significantly higher productivity. It is the promise of Dynamics 365 for manufacturing. The competitiveness of your businesses dictates the fact that the scalability of production processes is not only desirable but imperative. When we talk about scaling, we have to look at ways of expanding the value produced in addition to the quantity produced while simultaneously improving the quality of the output sustainably.

You can meet these requirements with Dynamics 365 for Manufacturing, which links well with others, such as Dynamics 365 Business Central. Through the utilization of the enhanced functionalities and AI Copilot in Dynamics 365, manufacturers can streamline their usual activities and get prompt and accurate reports.

Scaling Production Processes with Dynamics 365 for Manufacturing

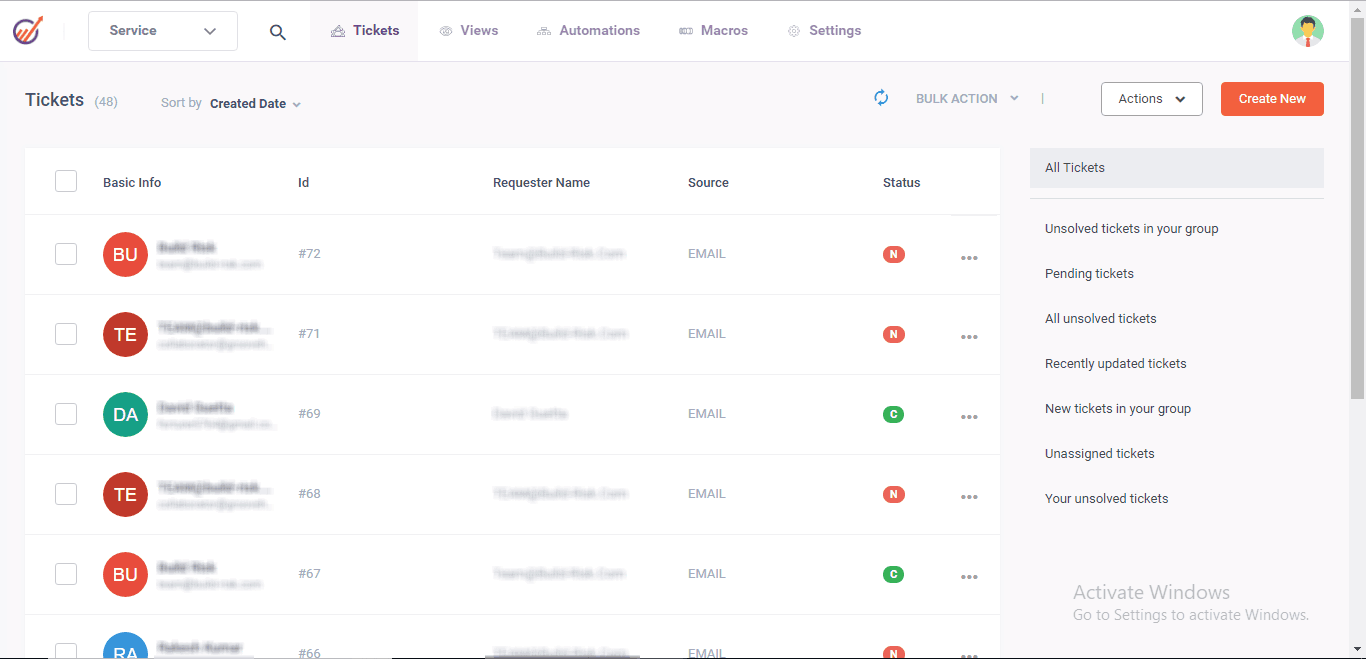

Dynamics 365 for Manufacturing is one solution designed to cater to manufacturing industries and their needs. It offers various features and facilities to enable different processes and make them effective and efficient to achieve better outcomes.

Key Features and Capabilities

Production Management:

Production management involves scheduling and monitoring the production process, and Dynamics 365 makes it easy to accomplish both. This way, you can work to allocate resources effectively, monitor work orders in real time, and even determine where there are any jams in the workflow.

Inventory Management:

Forget the situations in which your company is out of stock or has more than it can sell. It also allows efficient stock control in one or multiple facilities to prevent products from expiring through continuous restocking.

Quality Control:

Quality cannot be compromised in manufacturing processes. Also, Dynamics 365 offers solutions for quality assurance and control, which help set quality management standards, control defect rates, and introduce corrective actions to enhance product quality.

Supply Chain Management:

The supply chain is one of the significant factors in production because it informs whether the business is appropriately positioned to meet market needs. Suppliers, manufacturing, and even the customers’ interactions are well handled by Dynamics 365 in managing the end-to-end supply chain.

Improving Efficiency While Using Copilot in Dynamics 365

A core capability of Dynamics 365, Copilot is an AI-driven assistant meant to enhance human performance in certain tasks.

Automation and decision-making

Copilot is most useful for automating tasks, which are otherwise time-consuming and disruptive to the workflow. Whether it is data entry, appointment-making, or inventory, Copilot becomes the driver while staff becomes more productive and is directed to perform other, more critical tasks.

Besides, Copilot isn’t just about automation; it can also make smart decisions independently. As a result, Copilot gives real-time analysis for better and faster decision-making by simply crunching numbers and identifying patterns. Copilot is your go-to tool for enhancing operations, whether you are trying to improve the production calendar or find ways to save money.

Real-World Results

It is possible to imagine a manufacturing environment in which Copilot watches the flows of the production line, searches for inefficiencies, and corrects them. By addressing issues as soon as they are detected, Copilot maximizes efficiency, reduces time lost waiting for equipment, and, overall, increases revenue. For instance, Copilot uses historical data to help predict demand correctly so that manufacturers can order the right quantities of products without experiencing a loss from holding too much inventory or running out of stock.

Technical Considerations for Implementation

Infrastructure Requirements and Scalability:

Taking stock of your current IT environment and evaluating whether it is ready to host Dynamics 365 before you jump into implementation is pertinent. These factors include the number of concurrently connected users that the server can handle, the capacity of the network for transmitting data, and the storage space available for the files. Moreover, we cannot underestimate the possibility of growth; it is crucial for any business that plans to expand its market share.

Data Management and Integration:

Activities in the manufacturing process will create large volumes of data, from production parameters to supply chain data. However, given the sheer volume of data that needs to be generated, captured, and analyzed, strong data management practices must be in place to achieve this goal.

Security and Compliance Considerations:

Since the business data is sensitive, implementation should also emphasize security. Ensure proper precautions are taken against cyber threats and people who can gain unauthorized access to the information.

Customization and Configuration:

In reality, there is no single manufacturing operation to which any other is similar to how the various functions are performed, the processes followed, and the business rules being implemented. Hence, customization and configuration are important when considering the Dynamics 365 system.

User Training and Adoption:

Lastly, no technology implementation project is complete without a factor determining user acceptance and, thus, usage of the implemented technology. Ensure the employees undergo extensive training to become acquainted with Dynamics 365 and its various features.

Solutions Addressing Typical Problems in Manufacturing

Manufacturing is a rather complicated subject, and it is impossible to anticipate a situation where numerous challenges will not be by your side. Still, it is crucial to mention that all these challenges can be easily mitigated and even turned into the main drivers of success when the right tools and strategies are employed.

Optimizing supply chain management

One common issue for most manufacturers is the lack of effective supply chain management. Some disruptions may occur on the supplier side; such as delays in the delivery of supplies, issues with transport, or changes in market demand for the supplies. Supply chain management is now the most significant aspect of managing an organization. Dynamics 365 for Manufacturing has facilities to manage the supply chain totally and dynamically at every level.

Enhance inter-group cooperation and effective communication.

Dynamics 365 for Business Central can integrate seamlessly with Dynamics 365 for Manufacturing; this implies that all the teams will be working on a single platform. Since data feeds and real-time updates provide instant information; one can be in harmony with the rest of the team members to ensure everyone is in sync.

Improving quality control

Due to the defects, one may be forced to recall the products, harming the corporate image, raw materials, and customer complaints. The manufacturing functionality of Dynamics 365 is a complete system of quality management needed to produce high-quality products.

Wrap-Up: Scaling Production Processes with Dynamics 365 for Manufacturing

One of the critical factors affecting manufacturing profits is the rate at which products are produced, and Dynamics 365 for Manufacturing has all the functions to facilitate this. From supply chain management to raising the bar on the value of real-time production control; it’s your one-stop source for increased performance and business improvement. Understand how Dynamics 365 can assist in improving your business and enhancing its growth to be on par with competitors

Interesting Related Article: Guide to Emergency Management: What You Need to Know.